CHEMICAL RECYCLING | SCHEDULE A PICKUP | BUSINESS CLOSURE SERVICES |

How to Clean and Maintain Your Storage Tanks & Traps

Have you checked on your tanks & traps lately? Tanks are found in nearly every facility, are highly regulated and require maintenance. Tank cleaning should be conducted by licensed professionals. Many facilities also have a trap system that requires regular inspection and maintenance. Industries where we often find traps include Food Services/Industry, Automotive or other Manufacturing settings.

Below you will find three common types of storage tanks that require tank cleaning, and sometimes decommissioning. If you are not sure what type of tank you have, or if it needs maintenance, feel free to contact our team for a free consultation. We have many years of experience in tank and trap cleaning and maintenance and will help you determine the best course of action that meets the latest safety and regulatory guidelines.

Neutralization Tank Cleaning

Neutralization tanks are used to alter the pH level of corrosive waste drainage before being discharged into the sewer system. These tanks are attached to sewer lines and neutralize any acids by either dilution or chemical neutralization. Even if no acids are being sewered, neutralization tanks still fill up with sediment and can clog over time. Contact us to determine if your neutralization tanks are compliant with your local regulations or if they require maintenance.

Example

Below is an example of a neutralization tank that we serviced. As you can see, this tank required removal of old rock/sludge, packaging, testing, disposal, and installation of new rock. The old rock/sludge can have enough heavy metals built up to be regulated as hazardous waste; testing will inform that process.

Holding Tank Cleaning

Holding tanks are used to store products necessary for a manufacturing process and are found in most manufacturing facilities. Anytime a manufacturer has large quantities of liquid product that they need to hold and use continuously, they’re likely to have some sort of tank system for storage. Regardless of the product, these tanks will occasionally need to be cleaned out to remove sedimentary buildup, impurities, and to check the tank integrity. Often times, holding tank work is completed during regular plant closures in order to avoid interrupting the manufacturing process. Please see our Closure Services for more information on how we can support your regulated waste and removal during the process.

Examples

Watch a Customer Video About A Tank Cleaning Project

Demolition Project

- Cleaned-out four 2,500 gallon ink tanks, one 10,000 gallon fuel oil tank, two 5,000 gallon acid tanks

- Cleaned all associated process lines

- All tanks required confined space entry and appropriate PPE

Tank Clean-out

- Cleaned-out one 10,000 gallon sulfuric acid tank and one 10,000 gallon sodium hydroxide tank

- Waste neutralization

- No confined space entry

Maintenance Equipment & Tank Cleaning

If your facility is operating a boiler, you likely have back-up fuel holding tanks. These tanks also need to be cleaned regularly and checked for integrity. The size of the back-up tank is dependent on the size of your boilers. Virtually every school and multi-story office building is operating a boiler.

These tanks vary greatly in size depending on the size of the boiler. Many facilities are switching from #6 fuel oil to #2 fuel oil. If this is happening in your facility, the old #6 tanks need to be cleaned out before they can be decommissioned. Additionally, the #2 fuel oil tanks may require maintenance due to contamination or repurposing of tanks.

Examples

Underground Tank Clean-out, Large

- Clean-out one 325,000 gallon underground fuel oil tank

- Tank contained both #6 and #2 fuel oil

- Required confined space entry and appropriate PPE

Underground Fuel Tank Removal, Small

- Removal of one 1,500 gallon underground fuel oil tank

- Tank contained #2 fuel oil

- No confined space entry

Trap Cleaning

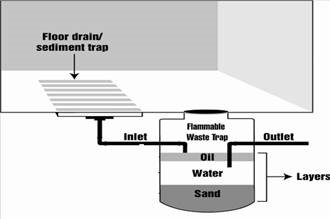

Traps are designed to prevent unwanted materials from going down the sewer drain. These are usually designed for petroleum products (oil and gasoline), sediments/solids, or both. Traps may also be part of a chemical spill containment system. Both trap types are meant to capture material instead of allowing it to travel through the sewer system. These captured materials must periodically be removed from the trap to allow proper functionality. Most facilities with active floor drains have a trap to capture sediment.

Example

In the example below, you can see an illustration of the three layers that have built up in a flammable waste trap. The oil/gasoline floats on top of the water while the sediments/sand sink to the bottom. If too much sediment enters the trap it will block the outlet pipe causing waste water to back up into your facility. Proper cleaning and maintenance removes the materials from inside the trap and refills it with the proper amount of water. These services can be done with a vac truck as most of the contents will still be pumpable. However, if the tank has been neglected, the sediment can compact enough that it is no longer pumpable and requires a confined space entry operation to physically remove the material by hand.

Trap Waste Analysis

The removed material is often not RCRA regulated as hazardous waste, but it must be sampled and analyzed by a certified lab to verify the regulatory status before it can be shipped off-site. With lab results our services will provide the proper removal option, all necessary disposal paperwork and we will have a truck pick-up the waste material from your facility.

Industries Served:

We support tank and trap maintenance services nationally for all industry types. Common industries requiring tank cleaning services include:

|

|

|

|

|

|

|

|

|

|

|

|